By improving product quality, manufacturers can reduce material costs while reducing warranty expenses and increasing customer satisfaction. Reducing waste helps companies save on both the cost of raw materials and disposal fees. Product cost is an essential factor in determining a company’s profitability.

Product Costing

- Put simply, understanding the costs of developing a product, feature, or update helps you make more informed decisions throughout the product lifecycle.

- This number is essential because it will help you determine how much you need to charge for your product to make a profit.

- If production costs varied between $20 and $50 per barrel, then a cash-negative situation would occur for producers with steep production costs.

- Product overcosting or undercosting is a big problem for most manufacturing companies.

- Direct labor costs include wages and salaries for workers directly involved in production, such as assembly line workers and machine operators.

- In some cases, business owners may also believe they can make up for any lost revenue by selling more goods or services.

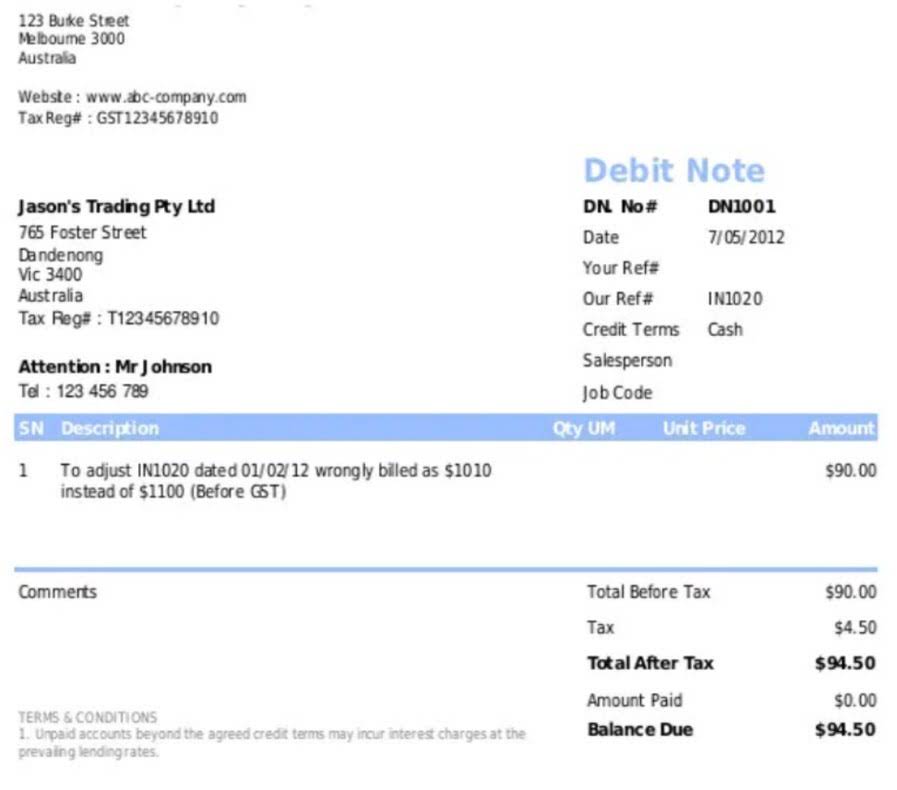

It refers to the total expenditure incurred in creating a product, including the cost of materials, labor, and overheads. Understanding product cost is essential for setting prices, managing budgets, and making strategic decisions. To arrive at the cost of production per unit, production costs are divided by the number of units manufactured in the period covered by those costs. Prices that are greater than the cost per unit result in profits, whereas prices that are less than the cost per unit result unearned revenue in losses. Production costs include labor, raw materials, consumable manufacturing supplies, and general overhead. Taxes, royalty payments, and licensing fees are also considered production costs.

Production Costs: What They Are and How to Calculate Them

Alternatively, customer research can show that you are on the wrong path and need to pivot. Time is money in this scenario, so you’ll want to consider how long you expect the development process to take and keep track of the actual timeline of events. Understanding how to properly categorize these costs helps you optimize your spending, prioritize investments, and ultimately, drive the company’s growth and success. In some cases, business owners may also believe they can make up for any lost revenue by selling more goods or services.

Manufacturing Overhead Cost

- There are a few reasons why business owners might undercost their products or services.

- Food businesses need to carefully manage their product costs to ensure they can offer competitive prices and maintain healthy profit margins.

- If a company consistently under costs its products, it may eventually go out of business.

- Companies can optimize their operations and improve their bottom line by understanding the relationship between direct costs and output.

- Product costs include direct material (DM), direct labor (DL), and manufacturing overhead (MOH).

Direct costs for manufacturing an automobile, for example, would be materials like plastic and metal, as well as workers’ salaries. Total product costs can be determined by adding together the total direct materials and labor costs, as well as the total manufacturing How to Invoice as a Freelancer overhead costs. To determine the product cost per unit of product, divide this sum by the number of units manufactured in the period covered by those costs. Data like the cost of production per unit or the cost to produce one batch of product can help a business set an appropriate sales price for the finished item. Since product costs include manufacturing overhead that is required by both GAAP and IFRS, product costs should appear on financial statements. To eliminate overhead costs, a manager may modify product cost when making short-term product and unit pricing decisions.

Understanding the Costs in Product Costs

In most cases, the price of a product should be set based on product cost consist of its cost, as well as market demand, competition, and other factors that affect the market price. Product and period costs are two different types of costs that are incurred in producing and selling goods. On the other hand, depreciation is an indirect cost typically assigned to all products a company produces. Depreciation represents the gradual reduction in the value of a company’s fixed assets, such as buildings, equipment, and machinery, over time due to wear and tear. Still, no more material is available for purchase (and, therefore, must be ordered at an additional cost). The company pays its workers $20 per hour, and it takes two hours to make one widget.

AccountingTools

For example, if a company makes a chair, the direct materials cost would include the cost of the wood, screws, and fabric used to make the chair. Many businesses use a standard cost system to calculate their product costs accurately. This system helps companies better understand their production process and identify areas where they can reduce costs to improve their bottom line. Direct labor costs include wages and salaries for workers directly involved in production, such as assembly line workers and machine operators.

Why is understanding product cost so critical

It’s important to note that this is a simplified formula and actual product cost calculations can be much more complex. For example, businesses may need to allocate overheads based on the proportion of resources used by each product, or adjust for changes in raw material prices or labor rates. Each of these components can vary significantly depending on the type of product and the manufacturing process. For example, a high-tech product may have high direct material costs due to the cost of electronic components, but relatively low labor costs due to automation. Conversely, a handmade product may have high labor costs but relatively low material costs. You may find yourself in a situation where you determine your production costs are more than you desire.

These costs can be either fixed or variable depending on the type of product being manufactured. Fixed costs remain constant regardless of how much is produced, while variable costs vary based on production volume. This not only helps you determine the next project to prioritize but also maximizes your profits. To qualify as a production cost, an expense must be directly connected to generating revenue for the company. Also, the overall cost determined under the overhead budget is converted into per unit terms to determine the cost of ending inventory.